Blind & De-Blind steps

Purpose of blinding?

A blind is a safety device used to isolate a section of a line or equipment when the line or equipment needs to be inspected for maintenance, repair, or removal from the service. It differs from a valve in that the blind is a permanent or long-term isolation device.

Types of Blind

Generally* Spectacle blind / Figure blind.

* Spade blind / Slip blind.

* Flange Blind.

* Spade blind / Slip blind.

* Flange Blind.

* Test blind / Vent blind.

Spectacle blind / Figure blind.

Spade blind / Slip blind.

Test blind / Vent blind.

Flange Blind.

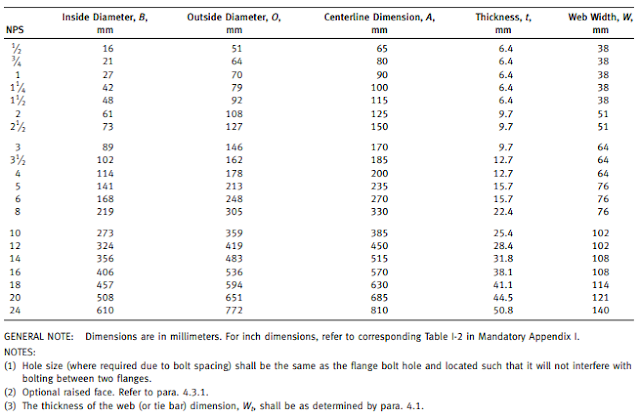

Dimensions of Class 300 Blanks for Use With Raised Face Flanges

Dimensions of Class 600 Blanks for Use With Raised Face Flanges

Dimensions of Class 900 Blanks for Use With Raised Face Flanges

Dimensions of Class 1500 Blanks for Use With Raised Face Flanges

Dimensions of Class 2500 Blanks for Use With Raised Face Flanges

Blind Activity ( Procedure)

* Go to the blind location and check the blind size and rating it's as per blind list correct or not.

* Confirm at a blind location what additional requirement. (insulation removed, or crane or scaffolding required). ( if required then arrange or inform your senior person)

* Arrange the new gasket and blind & tools at the location as required.

* Open the blinding permit and go to a blind location with the operation person and discuss the about work hazard and confirm the isolation valve and ensure that the drain and vent valves remain open.

* Barricade the work location and start blinding activity,(During the blinding activity, if found any type of sources such as liquid or gas stop the activity and report to your supervisor.) when the operation gives clearance then again start an activity, First bolt losing start from flange downside. after loose, all bolts, remove 50%bolts and make the proper gap between two flanges, and insert the blind between the flange with a new gasket, first do the flange alignment and proper tight the bolts for opposite opposite after all bolts tight. ( If required do the bolt torquing )

* After completing the blinding activity remove the barricade and perform good housekeeping, after close the work permit.

De-blind procedure

* Visually inspect all bolts and nuts for damaged or corroded threads. Replace bolts or nuts as necessary.

* Clean and lubricate the threads of the studs bolts.

* Clean the flange faces and check for scars the faces must be clean and free of defects (burrs, pits, dents, etc.) If at the location have a spectacle blind then reverse the blind

* Install the new gasket and be sure the gasket is properly centered. do not reuse old gaskets or use multiple gaskets.

* Check and properly do the flange alignment and adjust the position of the nuts to ensure that 2-3 threads are visible above the top of the nut.

* The first pass lightly tightens the first bolt then moves directly across or 180 degrees for the second bolt, then move1/4 turn around the circle or 90 degrees for the third bolt and directly across for the fourth. Continue this sequence until all bolts are tightened. the ( If required do the bolt torquing )

Comments

Post a Comment

rameshbhai.bamaniya@gmail.com